Specialised Welding

Specialised welding applications: Wear, Heat, Abrasion, Galling, Metal Repairs and Reclamation.

Hardfacing - Powder Welding - TIG / ARC / Gas Welding - Brazing.

Deloro hardfacing alloys are used to repair damaged camshafts or to build custom and performace cam lobe profiles. The hardwelded overlays risist galling and extend camshaft life.

Powder welding is normally applied using an oxy-acetylene torch. The component is heated with the torch and metal powder is introduced into the gas stream from a hopper before being transferred to the component through a flame. The powder coating forms a strong bond to the base metal by alloying and diffusion. Thus, powder welding results in a smooth, dense coating with a diffusion bond to the base material.

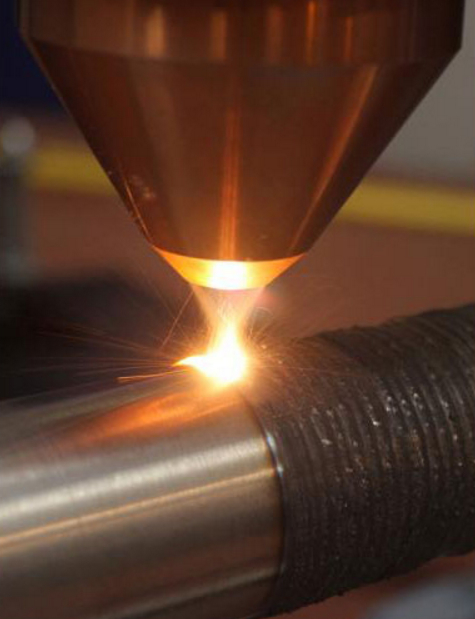

Laser cladding falls into the group of processes commonly known as hardfacing.

The laser cladding process is a method of applying a fully dense, metallurgically bonded and virtually pure coating which can be used to increase the wear resistance, corrosion resistance or impact performance of metallic components. In some cases, all three of the properties can be improved.

The process utilises a precisely focussed high power laser beam to create a weld pool into which a metallic powder is applied. The powder, which is carried by a stream of inert shielding gas, is blown coaxially through the laser beam.

More information on equipment here.