HVOF

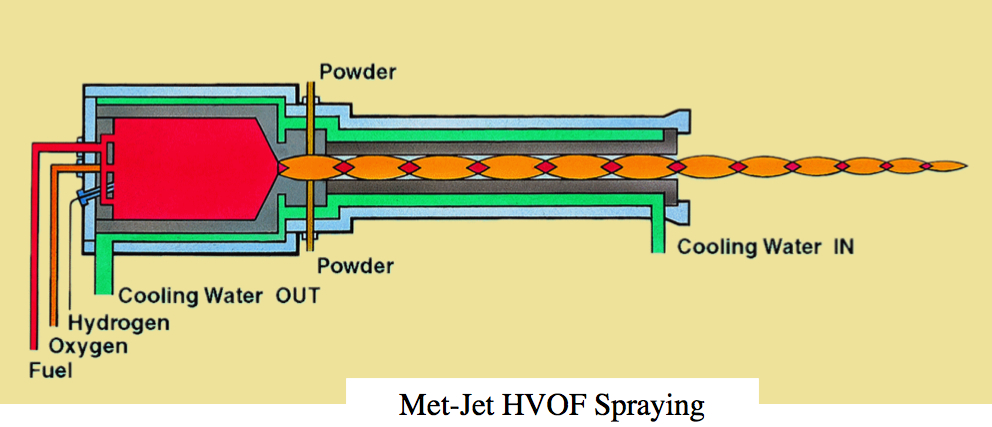

High Velocity Oxygen Fuel (HVOF) - High Velocity Acetylene Fuel (HVAF) is a process to apply very dense, strongly adhered coatings. A fuel (commonly kerosene or hydrogen) is mixed with oxygen and ignited in combustion chamber. The combustion gases are accelerated through a nozzle. Powder is introduced into the gas stream where it softens and gathers speed before coating onto the sprayed surface. HVOF/HVAF coatings are commonly used as a hard chrome replacement process and produce very dense, hard wearing coatings.

Heat Source: Fuel (liquid or gas) and oxygen flame

Material: Powder (metal)

Transfer: Via the flame

Process: The fuel is mixed with oxygen and ignited. The combustion gases pass through a converging/diverging nozzle and accelerate to around 1,500m/sec. The powder is injected into the accelerated flame where it softens and gathers speed. The high impact speed of the particles produces a highly adherent, dense coating structure.

met-pcc(hvof)

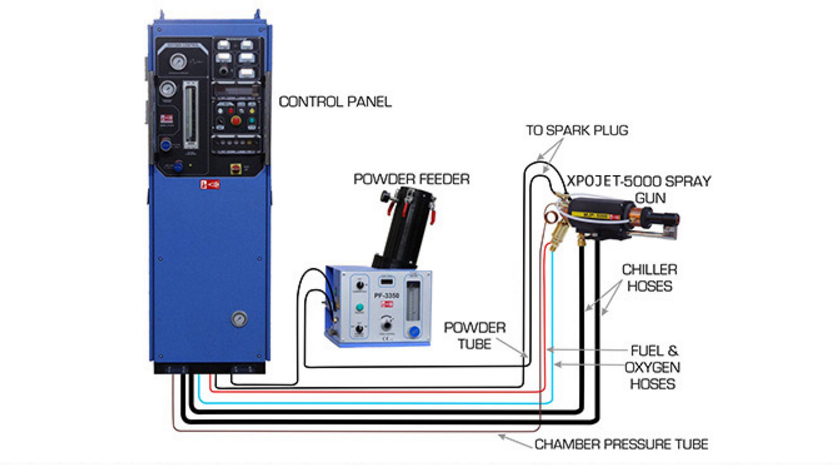

The Metallisation Met-PCC(HVOF) system is the latest development to our range of HVOF systems.

The Met-PCC(HVOF) system applies all of the simple control / operator interface features of our previous HVOF and Plasma systems. The ‘–L’ version can be interfaced with our own MET-JET4L pistol and/or other non-Metallisation liquid fuel pistols. The ‘-G’ version can be interfaced to a range of non-Metallisation gas fuelled HVOF pistols.

The Met-PCC(HVOF) system has re-packaged the control elements and utilised the latest technology to optimise functionality and reliability. At the front end, the operator interface utilises an intuitive Graphical User Interface (GUI), including the option to integrate video images into the display. The interface runs on a familiar touchscreen Windows PC platform with Intel Dual Atom processor which is great for usability, integration and communication. Behind the scenes, the latest PLC runs the system with communication between devices via the reliable Ethernet protocol.

As you would expect from a system of this standard, the gases/fluids are all mass-flow controlled for optimum repeatability of coatings. All spray parameters can have real-time trending on the system.

The result is a truly unique, compact design, flexible, easy to operate HVOF system, backed up by Metallisation’s 90 year+ industry experience and support.

Key features

- Mass flow control = repeatability

- Easy to use operator interface

- Liquid fuel = thick, low stressed coatings

- Various pistols can be used

- High hardness, low oxide level coatings

- PC control with touch screen

- Optional keyboard control

- Unlimited recipes and parameter recording

- Low running costs compared to hydrogen fuel

- High bond strength and low porosity coatings

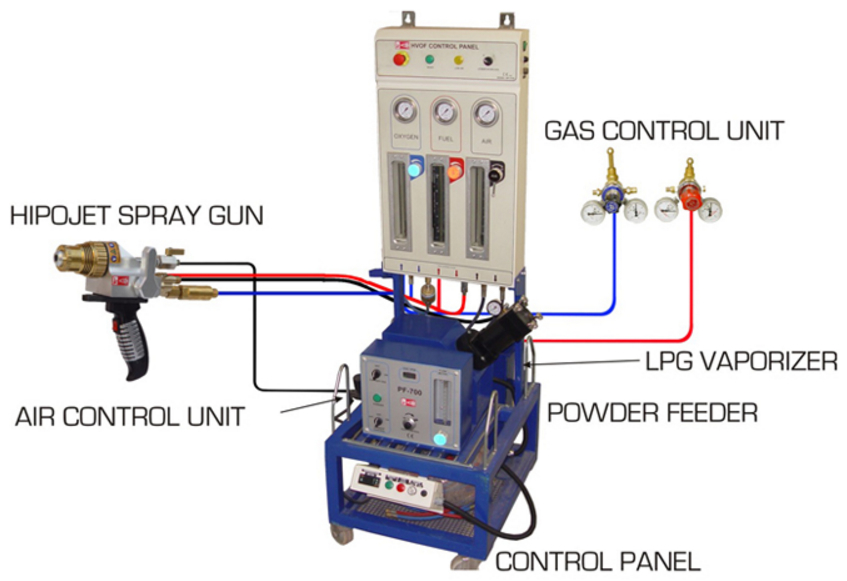

other systems available.