Plasma

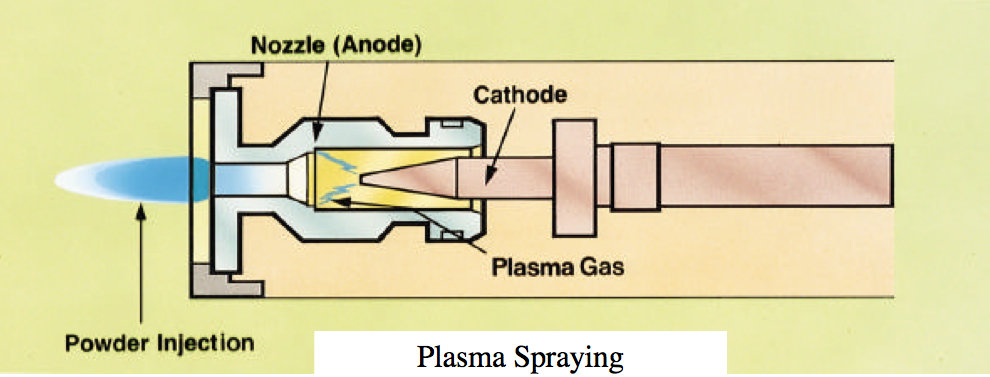

Plasma is the term used to describe gas which has been raised to such a high temperature that it ionises and becomes electrically conductive. In the case of Plasma spraying, the plasma is created by an electric arc burning within the nozzle of a plasma gun and the arc gas is formed into a plasma jet as it emerges from the nozzle. Powder particles are injected into this jet where they soften and then strike the surface at high velocity to produce a strongly adherent coating.

Heat Source: Plasma arc

Material: Powder (ceramic, metal, plastics)

Transfer: Via plasma jet

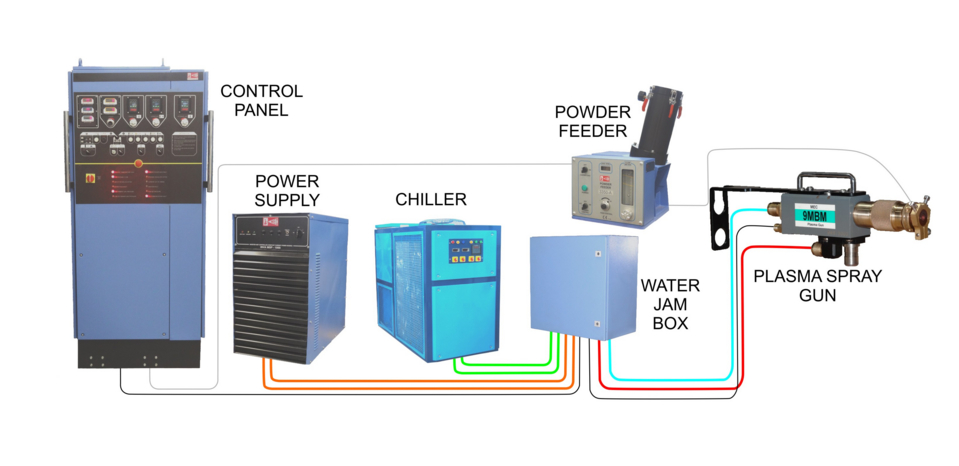

Process: Plasma is the term used to describe gas which has been raised to such a high temperature that it ionises and becomes electrically conductive. In the case of Plasma spraying, the plasma is created by an electric arc burning within the nozzle of a plasma gun and the arc gas is formed into a plasma jet as it emerges from the nozzle. Powder particles are injected into this jet where they soften and then strike the surface at high velocity to produce a strongly adherent coating. The work piece remains cool because the plasma is localised at the gun.

met-pcc(plas)

- Mass flow control of primary, secondary and carrier gases = repeatability

- Easy to use, intuitive operator interface

- Inverter power supply = stability

- PC control with touch screen operator interface

- Optional keyboard control or operator interface unit

- Manual or fully sequenced start-up, operation and shut-down

- Various straight, angled and extension pistols can be used

- Safety interlocks to prevent running without coolant and gases

- Argon or Nitrogen primary and Nitrogen, Helium or Hydrogen secondary gases

- Unlimited recipes and parameter recording

- Other powder feeders/power sources can be interfaced

other systems available.